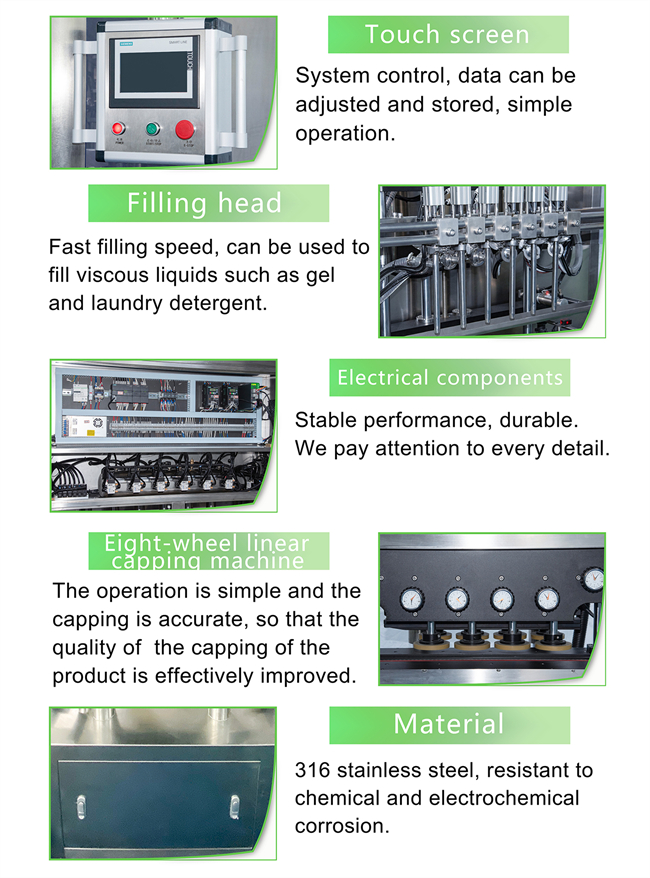

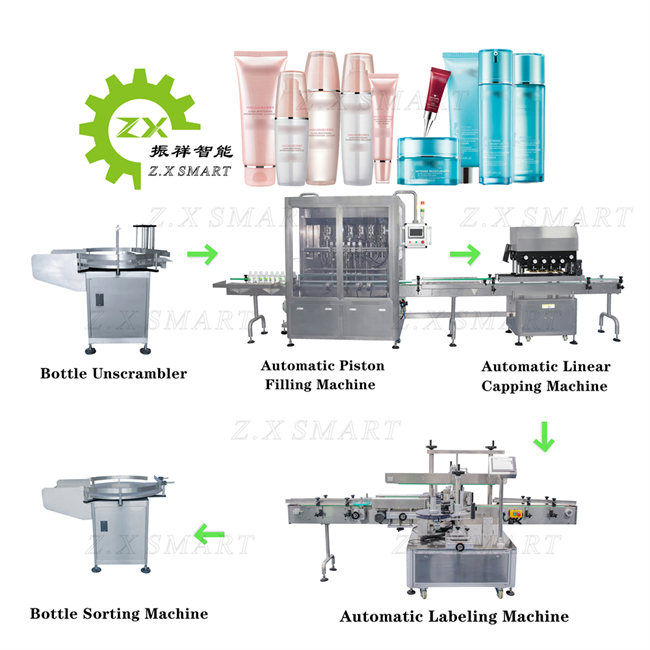

6 head piston filling machine

1. Number of filling heads: 6

2. Filling capacity: 0.5l-5l

3. Filling form: piston type, with multiple heads extending into the bottom of the bottle and rising while filling fast and slow

4. Filling speed: 6-8 bottles / min (4L bottles)

5. Filling accuracy: ± 1%

6. Material: the filling frame is made of 304# stainless steel

7. Program control: PLC + touch screen

8. Materials of liquid contacting parts such as filling nozzle and chute: 316# stainless steel, silica gel, POM

9. Air pressure: 0.6-0.8mpa

10. Conveyor belt: 114mm wide POM chain belt, speed 0-15m / min, ground height 750mm ± 25mm

11. Conveying motor: 750W variable frequency speed regulating motor

12. Power: about 2.2kw/380v three-phase five wire

13. capacity of main material trough: 200L (with liquid level switch, the feeding pipe is inserted into the bottom, and the material trough cover needs to prevent foam from overflowing).

14. The conveyor belt inlet is equipped with a double-sided bottle placing workbench: 2000x300mm (length x width)

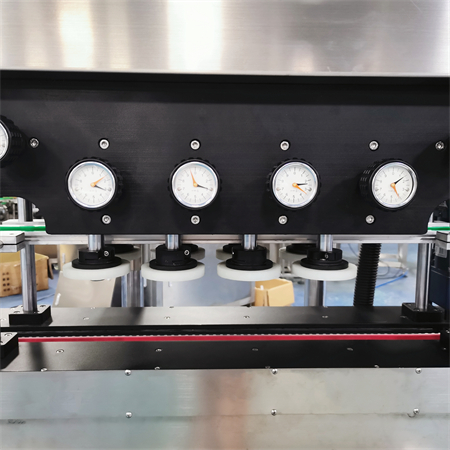

Linear capping machine

1. Suitable specification: according to the sample provided by the customer

2. Cover management method: hoist lower cover, hook cover

3. Form of screw cap: 8 wheel set rubbing screw cap

4. Speed: 2000 bottles / hour

5. The frame is made of stainless steel

6. Program control: PLC + touch screen man-machine interface

7. Overall power: about 1.2kW

8. Conveyor belt: 82 mm wide POM chain belt, height 800 ± 25 mm

9. Air pressure: 0.6 ~ 0.8MPa

Pneumatic claw capping machine

1. Suitable specification: according to the sample provided by the customer

2. Cover arrangement method: vibrating disc cover

3. Screw cover form: air claw type grab cover screw cover

4. Speed: 15-20 bottles / min

5. Conveyor belt: 114mm wide POM chain belt, speed 0-15m / min, height from the ground 750mm ± 25mm

6. Material: the frame is made of 304# stainless steel

7. Program control: PLC + touch screen man-machine

8. Overall power: About 800W

9. Air pressure: 0.6-0.8mpa

10. Power supply: AC220V, 50 / 60Hz, single phase

Double side labeling machine

1. Applicable labeling position: single side and double side labeling

2. Applicable product range: according to the samples provided by customers

2. Applicable label scope: according to the sample provided by the customer

3. Production capacity: > 30 bottles / min

4. Labeling accuracy: plane ± 1m (excluding the deviation of the bottle itself)

5. Voltage: 220V

6. Power: about 1.2kW

7. Conveyor belt: 114mm wide POM chain belt, speed 0-15m / min, height from the ground 750mm ± 25mm

8. Program control: PLC + touch screen man-machine interface

9. Applicable paper roll: inner diameter 76mm, maximum outer diameter 300mm

Bottle receiving turntable

1. Suitable specification: according to the sample provided by the customer

2. Rotary table diameter: 800mm

3. Height from the table top to the ground: 750mm

4. Material: the rotary table is made of 304# stainless steel

5. Power supply: 220V, 140W, 50Hz, single phase

6. Drive motor: 140W domestic brand AC motor

7. Speed regulation mode: variable frequency speed regulation